Michigan Commercial Doors premier partnerships with the leading manufacturers of Loading Dock Equipment and Levelers, allow for extremely competitive pricing and the fastest delivery in Southeastern Michigan. In addition to providing our customers with speedy delivery of loading dock equipment, MCD offers service and installation of all our dock equipment. Michigan Commercial Door can service all of your loading dock equipment or leveler needs in Detroit, Ann Arbor, Flint, Troy, Southfield and all of Southeastern Michigan.

Loading Dock Levelers

Mechanical

Patented holdown assembly allows for full float and automatic release capability with air ride trailers, preventing failure or damage from overextension

Simple operation with a cam and roller counterbalance system that assures smooth dependable walk down

Integral maintenance strut is lockout/tagout compliant with lip support strut

Yieldable Flip Lip w/Dampened Return

Single Point Spring Adjustment

5 Year Warranty

Dual pivoting cross-traffic legs for multi-position safety at dock level and below

Self-contained lip control yields under impact from incoming trucks

Built-in lockout/tagout maintenance inspection strut

Working range safety toe guards and night lock security

Lip keepers for cross-traffic support and automatic night lock security against theft

Levelers painted gray

Two laminated 4-inch 1014 bumpers are standard. 6-inch 1014 bumpers are optional

Capacities of 25,000 to 55,000

Hydraulic

Easy push-button operation for smooth, consistent operation with a hydraulic system that provides for full float at all positions

Positive lip extension and retraction with true regenerative hydraulic control

Below-dock end load capability

Full-width rear hinge mounted in compression with structural channel support

Velocity fuse hydraulic fail safe stops platform with 1-3-inch in free fall situation

Subframe design allows for easy quick pit clean out

Integral maintenance strut is lockout/tagout compliant

5 Year Warranty

A velocity fuse limits the unit to a 1″ to 3″ drop in a fully loaded free fall situation

Full range telescoping toe guards close off sides even in highest position

Built-in lockout/tagout maintenance inspection strut

Lip keepers for cross-traffic support and automatic night lock security against theft

Levelers are painted grey

Two laminated 4-inch 1014 bumpers are standard on the 25,000-55,000 pound CIR units

Two Laminated, 6-inch 1014 bumpers are standard on the 75,000 and 100,000 pound CIR units

Truck Restraints

Edge of Docks

Mechanical

Dual-extension spring lift mechanism

Heavy-duty self-storing steel lever with EZ grip handle

Roller-bearing lift mechanism for easy lifting

Cold-rolled steel hinge pins for added strength and long life

High-strength steel safety tread plate, minimum 55,000 PSI yield strength

Grease fittings

Milled lip edge for smooth tire rollover

Four steel gussets for added strength and extended life

Full-width distribution bar for extra durability

Heavy-duty bumper block assemblies with Tuf-Cord 4-inch 1014 rubber molded bumpers

Bumper projection—15 inches

Hydraulic

NEMA 4 push-button control panel

Cold-rolled steel hinge pins for added strength and long life

Fully hydraulic lip and deck cylinders

Grease fittings

Heavy-duty bumper block assemblies with reinforced rubber molded bumpers

Bumper/blockout projection—18 inches

115/230 VAC single-phase powerpack

Dock Seals

Cover material and wear pleats are top-grade fabrics providing superior performance and maximum durability

High-density polyurethane foam provides long life and excellent resiliency characteristics

Foam is bonded with high strength adhesive to select grade pressure-treated, kiln-dried wood framing for long-lasting installation

Standard size

side pad projection is 16″, maximum is 24″

hood drop is 24″

side pad penetration is 12″

Heavy-duty galvanized mounting hardware

Full-height yellow guide stripe standard

Hood drop can be customized to accommodate the truck heights at your dock

Brass grommets with spur washers for venting

All sew lines are locked stitched utilizing heavy bonded polyester multifilament thread with UV protectant for extended life

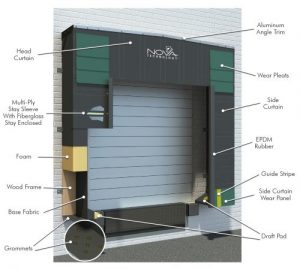

Dock Shelters

Rugged EPDM rubber components effectively block air and light gaps around trailer door hinges while having incredible wear and weather resistance

Cover material and wear pleats are top-grade fabrics providing superior performance and maximum durability

Impactable side pad structure protects unit from damage against off-center trailers

High-density polyurethane foam

Select grade pressure-treated, kiln-dried wood framing

Raked header with translucent fiberglass top

Flexible fiberglass stays add stiffness to shelter face curtains

Aluminum angle face edging on head frame

Detachable side curtains and draft pads use Velcro® for easy removal and are re-attachable within minutes for routine maintenance

Heavy-duty galvanized mounting hardware

15-inch yellow guide stripe standard

Wind straps on head curtain keep the head curtain from being blown out of position

All sew lines are locked stitched